Welcome to Baron Technology

ISO Certificate: ISO 9001:2015

Welcome to Baron Technology

ISO Certificate: ISO 9001:2015

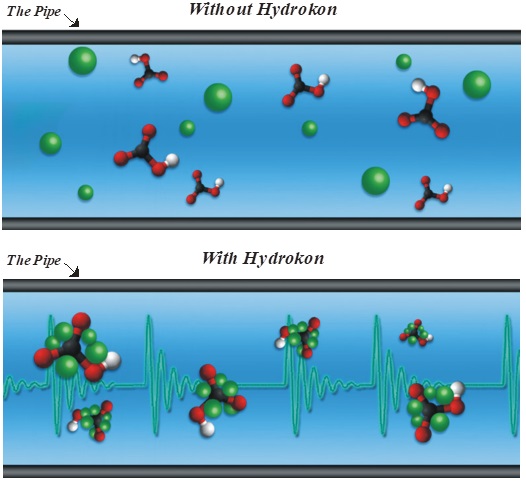

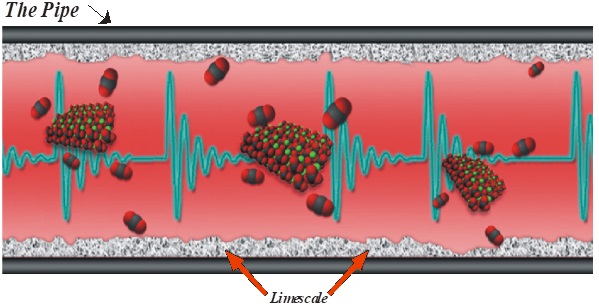

The Hydrokon system controls scaling by changing scale forming ions to neutral molecules with our positively charged electrode and ground. These stable molecules stay in suspension rather than attaching to wetted surfaces as scale. This is done on a continual basis during the normal recirculation of water past our electrodes. Removing the ions from the water also allows the water to dissolve existing deposits. The continual recirculation of the water also controls biological growth by raising the pH of the water and by the flow of water through our electrical fields.

An electrostatic water treatment unit for use in any water circulating system where SCALE is a phenomena is now available from Baron Technologies, Hyderabad, Telangana, India.

Water when subjected to electrostatic field changes the characteristics if scale forming compounds and throws off their equilibrium. This change in water scale forming compounds incapacitates them from causing or forming scale. The compounds are converted to colloidal forms which are kept in suspension. These colloidal do not even adhere to metal surfaces.

These colloids or the accumulation of TDS gets out of the heat exchangers during blow down. In circulating systems, they tend to settle down at very low pressure zone in the tanks which need to be flushed out whenever the conductivity limit exceeds 2500. This occurs once in a month or it depends on the raw water condition.

The most important feature involved is producing the required electrostatic charge. Experiments have been done with magnets, combination of metals and electricity. Only use of electricity in creating the electrostatic field has proved to be successful. This technology is proved to be the most powerful energy of the three. The power required is synchronized from the power pack to the electrode which is housed inside the water treatment chamber. The power is synchronized with the capacity, water conditions, water flow rate and pipe dimension

HOW ELECTROSTATIC HYDROKON WORKS

Electrostatic water treatment involves the passing of system water through an imposed d.c. or static electric field. Electrostatic water treatment has been proposed to operate as a dispersant to foulants, particularly calcium carbonate particles. It has been theorized that the electric field passing through the water will in effect induce a like surface charge on foulants and calcium carbonate particles. The similar charge on particles will prevent agglomeration and as a result deposition will be decreased. It has also been theorized that electrostatic water treatment can inhibit the growth of bacteria.

Typical Connection Fittings.

Typically, electrostatic water treatment devices are installed in cooling water systems either in a pipe bend configuration or a side stream configuration. An electrostatic water treatment device consists of a voltage supply, an electrostatic rod and a reaction chamber. The insulated electrode rod is placed inside of the reaction chamber and water is allowed to flow in the reaction chamber and around the electrode. The voltage supply delivers a DC voltage at a specified level and current limit to the electrode. Water Systems typical voltage and maximum current levels are 12,000 V and 0.02 - 0.45 mA.

Equipment Specifications

TECHNICAL SPECIFICATIONS FOR ELECTROSTATIC HYDROKON ON LINE NON-CHEMICAL WATER TREATMENT SCALE PREVENTER.

THE ELECTROSTATC HYDROKON Unit Consists of Following:

Electrostatic Hydrokon systems are complete, self-contained, loaded and ready to use. A simple inlet and outlet connection is all that is required for installation. Please review operating pressures, temperatures and water chemistry limitations to ensure compatibility.

Specifications Inlet/Outlet Connection:

3/4” -20” (multiple options)

Temperature : 40° - 110°F

pH : 6.5 to 9.5

Water Hardness 50 to 2000 ppm

Water Pressure : 15 min.- 100 max (PSI)

Using ELECTROSTATIC HYDROKON no other water treatment equipment only of particles scale bleeding in cooling towers sump.

An important note about iron, manganese and copper in the water supply.

Iron and Manganese

Just as with conventional water softening media, HYDROKON needs to be protected from excess levels of certain metals that can easily coat the active surface, reducing its effectiveness over time. Public water supplies rarely, if ever, present a problem, but if the water supply is from a private well confirm that the levels of iron (Fe) and manganese (Mn) are less than 0.3 mg/L and 0.05 mg/L respectively. Copper should be less than 1.3 mg/L.

Copper

Copper usually originates from new copper plumbing upstream of the HYDROKON system. If this condition exists, we recommend waiting 3-4 weeks before placing the system in operation. This will allow the copper surfaces to be fully flushed and develop a natural protective surface. To further minimize any problem with excess copper the plumbers should be advised to avoid applying excess flux on the inner surfaces of the pipe and to use a low-corrosivity water soluble flux.

(a) Sufficient water is being passed to fulfill process conditions.

(b) Flow requirement to enable ELECTROSTATIC Hydrokon to function efficiently are being achieved.

THE ELECTROSTATIC HYDROKON SYSTEM WILL WORK EFFICIENTLY WITH CORRECT WATER FLOW RATE & BLEED

FLOW RATE

A minimum flow rate is the most critical condition for effective operation.

The minimum flow rate required is 7 ft. per second over the system itself. The selection chart is shows the size of unit required to treat a particular flow rate.

In order to achieve a satisfactory flow rate it may be necessary to install a unit of as given in the selection chart and that of the circuit pipe. If the flow rate is too low, the Electrostatic Hydrokon systems will itself scale up, thus insulating it and rendering it ineffective.

DISSOLVED SOLIDS

For scaling to be prevented, the concentration of dissolved scaling salts must still be kept under control. In general a maximum TDS level of 3000 PPM is recommended, although higher levels may be found to be satisfactory in certain circumstances. A good bleed on the system is, therefore, essential to counteract the concentration of cooling towers base tank is also recommended particularly in the per/week of operation

MAINTENANCE

The ELECTROSTATIC HYDROKON SYSTEM is maintenance free, provided that it has been correctly installed and the simple operating instruction is followed. It may occasionally require cleaning of cooling towers base tank, but check the after water test report with computer simulation report doing so.

While it is possible to operate cooling towers at higher levels of conductivity, continued bleed of the system is necessary to keep concentrations of particulate matter at appropriate levels. Water use and discharge fees will be reduced as a result of operating at higher conductivity levels. Except in special conditions the normal and proper operation of a tower will involve bleeding or blow down to maintain the water conductivity at between 3200 and 3800 mS/cm of conductivity.

Bleed off in cooling tower bottom: A bleed is set for following months:

Things to watch for: During the first 30-90 days:

in the calcium in the water because HYDROKON is removing old scale deposits from pipes & condensers.

Good practices:

The Electrostatic Hydrokon system before installation, we recommend that you clean by HCL Acid of HEAT EXCHANGER / CONDENSER tube ,Cooling Towers etc.

We also recommend that you drain your water Cooling Towers sump. This should be done7 to 15 days after Electrostatic Hydrokon is installed, and again in one year. This is a good practice that can dramatically increase the life of your water cooled appliance.

Conditions

Our obligation under this warranty with respect to the Electrostatic Hydrokon is limited to furnishing a replacement for, or at our option, repairing any part or parts to our satisfaction that prove defective within the warranty period stated above. Such replacement parts will be delivered to the owner F.O.B. nearest factory, at no cost, excluding freight and local labor charges, if any.

Our obligation under this warranty with respect to the Electrostatic Hydrokon media will be limited to furnishing a replacement for the media within two years from date of original installation. Such replacement media will be delivered to the owner F.O.B. Factory, at extra cost, excluding freight and local labor charges, if any. Damage to the media, other oxidizers or fouling or any other operation outside of the limits shown under Specifications, is not covered by this warranty.

Note: Electrostatic Hydrokon shall not be liable for freight, handling or labor charges, or consequential damages.